About Us

Leading the Future of Turbine Machinery Innovation

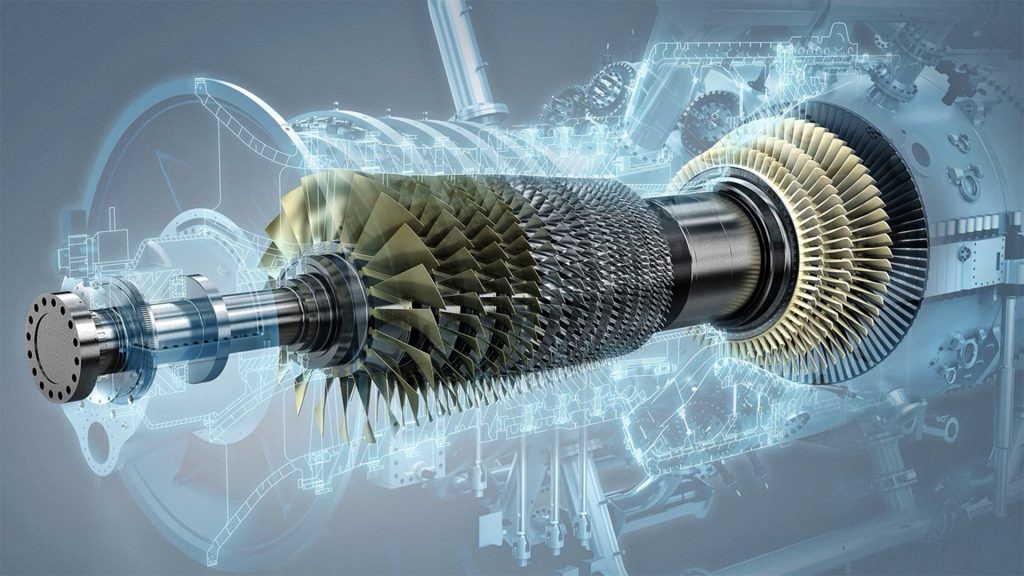

At Power Turbo Technica, we are more than just manufacturers—we are engineering pioneers dedicated to advancing turbine technology. Since 2006, we have built a legacy of precision, reliability, and innovation, supplying mission-critical turbine components to industries worldwide. From power generation and aerospace to oil & gas and marine propulsion, our solutions drive efficiency, performance, and sustainability in the most demanding applications.

Our Mission

To engineer ultra-precise turbine components that maximize energy efficiency and durability for global industrial applications.

Our Vision

Leading the evolution of turbine technology through cutting-edge manufacturing, sustainable practices, and relentless innovation.

Our Story: Engineering Excellence Since 2012

Founded in 2006 as a small machining workshop, Power Turbo Technica has grown into a globally recognized supplier of high-performance turbine machinery parts. Our journey has been fueled by:

A passion for precision engineering

Relentless R&D investment

A customer-first philosophy

Adaptation to evolving industry demands

Today, we operate state-of-the-art manufacturing facilities equipped with CNC machining, 5-axis milling, laser welding, and advanced metallurgy labs, ensuring every component meets the strictest tolerances and performance standards.

WE ARE THE SUPPLIER OF STEAM TURBINE SPARE PARTS SUCH

1. SEALING FINS OF DIFFERENT ROTORS AND GLANDS

WE SPECILIASE IN THE BELOW SEALING FINS AND CAULKING WIRES.

GLAND FINS, ROTOR FINS, GUIDE BLADE CARRIERS(GBC), ROTOR INTERSTAGE

FINS, SEALS, SEGMENT PARTS, 4,6 PARTS SEGMENTS, FACE FINS ALL IN DIFFERENT

SHAPES AND SIZES SUCH AS L, J, U, Fins (L, J, U, 400, 600), DIAPHRAGMS, LP CARRIER AND HP CARRIER FINS.

WE USE IMPORTED MATERIAL OF BOHLER UDDEHOLM- DIN EN ISO 9445.

WE HABE MULTIPLE SIZE STRIPS FOR FINS ROLLING.

STRIP GRADE “X20CrMo13, NIMONIC, INCONEL, MDN 321” AND MORE.

STRIPS THICKENSS FROM 0.25MM AND WIDTH VARYING FROM6.5MM TILL 21MM.

WE USE SPECIAL STRIPS FROM BOHLER FOR STEP FINS OF THICKNESS 0.6MM, FOR LP CARRIER AND HP CARRIER FINS.

2. CAULKING WIRES

WE USE DIFFERENT SIZES OF CAULKING WIRES IN DIFFERENT SHAPES AND SIZES.

GRADES WE USE ARE “X10Cr13, X5CrNi18-12, 321,304” AND MANY MORE.

VARYING SHAPES ARE SQUARE, RECTANGLE, FLAT, OVAL, HALF ROUND AND ROUND WIRES.

WE CAN MANUFACTURE ANY CUSTOMISE SHAPE OF THE WIRE DEPENDING ON CUSTOMER REQUIREMENT.

SIZES VARYING FROM 1.0MM SQUARE TO 5X3MM ALL CAN BE MANUFACTURED ACCORDING TO CUSTOMERS REQUIREMENT.

3. BRASS, SCRAPPER RINGS AND ALLUMINIUM FINS

OIL GLANDS SEALS, BRASS FINS, SCRAPPER RINGS, ALLUMINIUM FINS ,

ALL IN DIFFERENT THICKNESS OF THE STRIPS AND SIZES.

- WE ALSO SPECILIASE IN CAULKING SERVICE OF GLAND AND ROTORS,

FOR ON SITE WORKS, JOB WORK etc…